Case Studies

Ellis Seeds

Ellis Seeds has a long history of working in the seed industry in Southern Manitoba. Simon Ellis, the current owner/manager, is a fourth-generation seed producer based a farm near Wawanesa (see their website for more details).

In 2015 Warren Ellis, who was the owner of the seed plant at that time, contacted One-Step Automation to discuss upgrades to the seed plant control system. We proposed a state-of-the-art computerized system with much more monitoring in the plant than their current system had. This would allow for faster response to alarm conditions, thus providing a greater measure of peace of mind for the operator.

We proceeded to install the various sensors and connections to exiting equipment and by fall of that year the new system was being commissioned and ready to run production. The system is operated from a touchscreen computer with a graphic layout of the plant which provides a quick overview of what’s happening in the cleaning line.

Warren was also working on a design concept for a seed treating system that would have a high throughput of product. His goal was to build a treater that would greatly reduce the wait times in the treatment process.

One-Step Automation built a control panel for this treater system which included a touchscreen interface, speed control for up to 3 chemical pumps and chemical metering, as well as continuous flow scale readings that also provides a totalizer of product treated. The program guides the operator through selecting which bin to pull product from, how much chemical to apply based on manufacturer’s recommendations and then select how much product he wants to treat. From there the process is fully automated and everything stops when the desired amount is dispensed. The whole process is approximately 4 to 5 times faster than tradition seed treating options that are commercially available!

Both systems have been in constant use since commissioning in the fall of 2015 and continue to provide reliable service to Ellis Seeds.

Contact One-Step Automation to discuss your control needs. We can be reached by email at sales@onestepcontrols.com or by phone at (204) 388-4101.

Sewage Treatment System

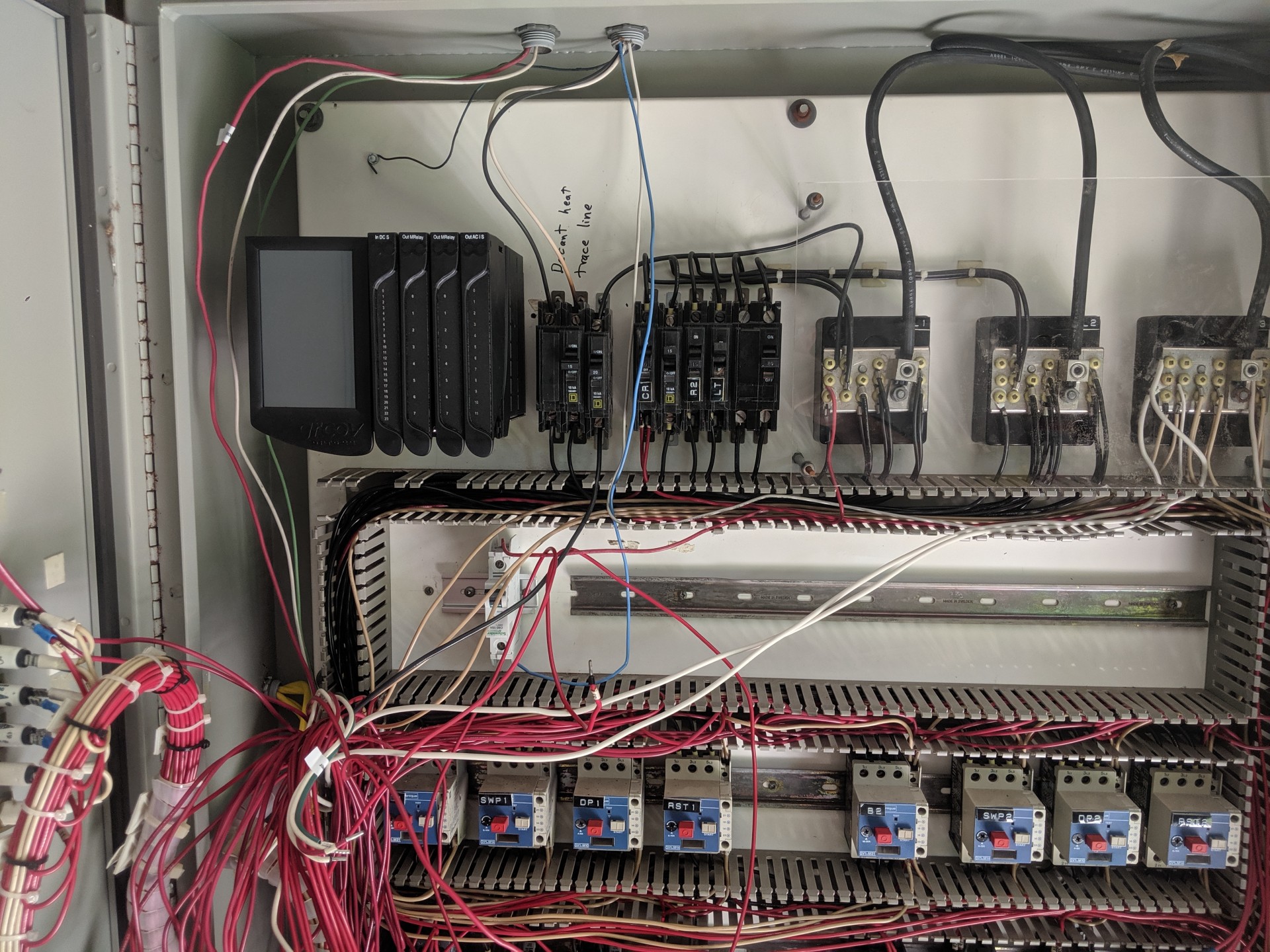

Some time ago we had a call from the maintenance manager at camp in the Manitoba Whiteshell region regarding their sewage treatment plant. They have what is called a Sequencing Batch Reactor system and the control panel needed some upgrading. One of the issues they were experiencing was that because of the corrosive environment, the wire connection between the control touchscreen and the PLC would no longer function. They were still able to operate the plant using the manual control switches on the front of the panel, but this required someone to be constantly checking on the plant and setting switches in the right sequence at appropriate times.

Our proposal to them was to replace the PLC with the new state-of-the-art EPIC controller which incorporates the ability to control and monitor the system remotely from a Smartphone. This approach was particularly appealing because it would eliminate the need for a touchscreen in this harsh environment.

It was decided to remove the existing PLC and install our new EPIC controller in the same spot in their panel. As you can imagine, down time at a sewage treatment plant must be as brief as possible so using this approach allowed for a fast transition to the new control system with minimal interruption to the treatment process.

The new control system was installed in July of 2019 and has greatly reduced the amount of time the maintenance staff has had allot the SBR process. The system runs completely automatically and requires little to no attention from the maintenance staff as far as the controls go.

Having enjoyed being at this camp a few times myself (Brian) a number of years ago gave us extra incentive to do this project to the best of our ability and at a reduced price.

In the past, Brian has also worked as a water treatment plant operator for over 20 years, so if water or sewage treatment controls is something you need help with, give us a call at (204) 388-4101 or email sales@onestepcontrols.com.

Keating Seeds

Mark Keating was running an older seed plant and wanted to increase production in his facility. He contacted One-Step Automation to see what could be done in his existing plant. So in the fall of 2013 we designed and installed an automation system that allowed him to run the plant to maximum capacity.

But Mark was dreaming of a larger, new facility and when those dreams started turning into more solid plans, he again contacted One-Step Automation to discuss automation for the new plant he was going to build. By mid-2020 One-Step was diligently working on a new automation design for this installation. This new plant would incorporate some new design ideas, one of which was continuous flow monitoring and logging of what was being processed in the plant. This involved One-Step Automation collaborating with two other businesses based in Manitoba to provide the data Mark was looking for in this facility. One was the mechanical equipment needed for the flow measurement and this was supplied by MeterVeyor. When connected to our control system this equipment provides the flow data on a continuous basis. This is where the second collaborating company came in, which is Seedtrakr and they specialize in inventory tracking and data logging. So with these companies working together with One-Step Automation we can provide not only a continuous flow summary of what’s being processed but also an accurate synopsis of what has been transferred to the long-term storage bins on Mark’s yard site.

This installation is a good example of what can be accomplished through collaboration with different service/equipment providers. If you have a project that needs some customized solutions, contact us and let’s see what we can come up with. We’re always up for a challenge!

J.S. Henry & Son

Back in 2009 Eric was faced with a dilemma, he was running a seed plant that required constant attention, but he also had a young family that was involved in various activities in the community. The seed plant had no automation or monitoring in place so it required frequent checking by the operator to make sure everything was functioning as it should. In order to maintain production levels Eric needed to be at the plant. However, he didn’t want to sacrifice time with his family to keep the plant running.

He contacted One-Step Automation to see if we could come up with a solution that didn’t require so much hands-on supervision at the plant. We designed and installed a control system that would monitor all the machines, conveyors, bucket elevators and bin levels. Eric got electric gates installed and well as electric 2-way valves. This allowed us to automatically switch bins if one filled up or use another supply bin if product ran out. With various feedback comments from Eric, we were able to create a system that functioned very well and freed up some of Eric’s time for other responsibilities.

In 2015 Eric decide to completely rebuild his seed plant and installed new equipment and of course, a new automation package from One-Step Automation. This new package included contactor panels, variable speed drives and a new touchscreen control station. With remote access into the control system, One-Step Automation is able to log in and make changes to the programming when the operator sees a need to change how certain items function.

The control system has functioned very well and has led to several other control projects at the J.S. Henry location. Eric commented that he’s “happy to support a family enterprise that is committed to the ag industry and that works hard to get to know your situation and issues in order to develop working solutions.”

Willowdale Seeds

The Wyrich family of Oakbank, Manitoba was planning to build a seed cleaning plant on their farm and were in need of a controls system for this venture. Contact was made with One-Step Automation and we began the process of finding out what they needed and how we could meet that need. Cleaning forages would be the primary focus of this plant, but they would also have the ability to clean other crops for use on their farm.

One-Step Automation supplied the contactor panels, variable speed drives and touchscreen panel to run this plant. The automation package includes the various sensors for monitoring machines, conveyance equipment and bin levels. When everything was installed and ready to run, One-Step Automation did a thorough pre-startup check to make sure all components were going function correctly. We then moved to the commissioning phase which again thoroughly tests every aspect of the control system. An important step in this process is the operator training that we provide. This is especially helpful for new operators that have not had a seed plant before. By the fall of 2018 the plant was in full production mode, with another satisfied customer.

In 2020, the Wyrich brothers decided to add a blending and bagging plant to their operation. Again, One-Step Automation consulted with them and came up with a plan for a controls system for this plant. The plant draws product from 5 different bins which gets blended into the various mixes they produce. The control system is connected to scales in the plant to make sure the correct amount of each ingredient is brought into the mixer. Once mixed, the product can be put into totes or smaller bags. The bagging system has its own controls for an automatic pallet stacking system.

Our experience with connecting to scales and other third-party equipment allows us to offer an efficient and accurate control package for a variety of applications. In this case the blending and bagging plant allowed the Wyrich brothers to expand the product line Willowdale Seeds has to offer and thus increase total sales.

Fox Lake Ag

Dry Fertilizer Blending

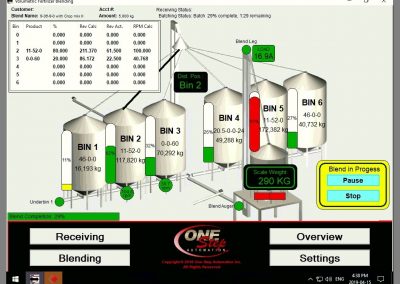

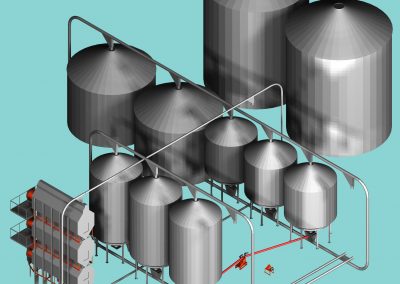

In the fall of 2017 Fox Lake Ag was building a fertilizer blending plant at their location in Hannah, Alberta. The project was being done by a general contractor who arranged for the purchase of the bins, conveyors, bucket elevators, etc. Part of that purchase also included a control system to blend the product to specific standards. The system was designed to produce 200 M ton per hour of finished product. So the challenge was to provide an automation system that was capable of a high degree of accuracy at high speeds.

We were contacted to provide a volumetric fertilizer blending program for this site. The general contractor had engaged the services of a consultant who had over 20 years’ experience in the fertilizer blending industry. With input from this consultant One-Step Automation developed a software package for the receiving, blending and dispensing of dry fertilizer that proved to be extremely accurate. On this particular installation after one season of operation the accuracy of blended product dispensed came to within 99.98% of the amount requested! On a more recent calculation where the operator asked for a total of 339,040 kg of product over a period of time, our system blended a scaled amount of 339,060 kg! We believe this level of accuracy is unmatched in the volumetric blending industry.

All control is done through an industrial grade touchscreen computer and the operator has the ability to repeat batches as needed. The overhead scale bin has enough capacity to a fill a semi-trailer at one time. The operator can select how much product to dispense to each compartment of the trailer allowing the loading of the trailer to be accurately distributed across all available space. The control system generates a report that is electronically transmitted to the accounting office indicating how much product was given to each customer. This eliminates the potential errors that can arise from manually entering figures into individual invoices.

The control system keeps a running inventory of each of the ingredients on hand and if a requested blend needs more of an ingredient than is a available, the operator will receive an on-screen alert message and the blend will not proceed without operator intervention.

The volumetric blending program has proven itself through several seasons of use at multiple sites.

(Fox Lake Ag has since been sold to Westview Co-op and we continue to provide support as needed.)

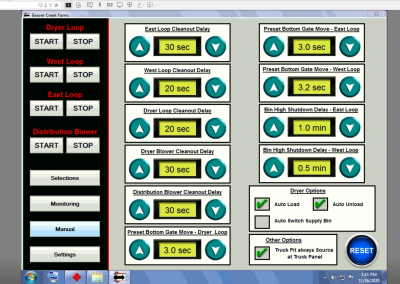

Beaver Creek Farms

Beaver Creek Farms is a large potato and cereal crop farm near MacGregor, Manitoba. In 2012 they decided to expand their on-farm grain handling & storage facility by a considerable amount. This included a new grain dryer, some additional bins and conveyance equipment. They also wanted to automate this system as much as feasible. With their years of experience on the farm they had a good concept of what they wanted to the control system to be capable of. They contacted One-Step Automation and discussions began on what they would like to see and what we would be able to offer.

They had come up with some interesting design features and we were able to couple our controls system to it for an excellent solution to their grain handling/drying/storage facility. The facility is built so that a semi-trailer can unload both hoppers of a trailer at one time, allowing for an extremely efficient unload process. The grain is then moved to either long-term storage or a holding bin for the dryer system. The dryer, with its own control system, is a high-capacity continuous flow unit. This requires the ability to move dry grain as well as wet grain at a fast pace. The One-Step Automation system can seamlessly coordinate the unloading of trucks, as well as the supply and take-away from the dryer. There is also the ability to transfer grain to the dryer holding bin from other bins connected to the system without an operator being present. This allows the dryer to run continuously through the night while the operator gets a good night’s rest.

The control system has gone through a few revisions since its first installation with the most recent being the addition of more bin high level monitoring. It continues to perform well and more than meets the needs of this facility.